Green Homes, Durable Designs: Sustainable Pvc Coated Fabrics

Share Post

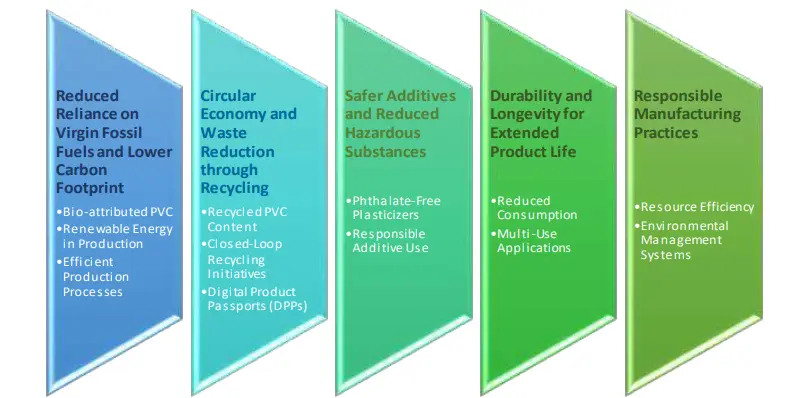

PVC is inherently non-biodegradable, and its incineration releases harmful chemicals into the atmosphere. Furthermore, the plasticizers commonly used in soft PVC can emit toxic fumes throughout the material’s lifespan, and the manufacturing process itself contributes to the release of toxic chemicals into the environment. Recycling PVC coated fabrics presents a complex challenge due to their multicomponent nature, making material separation difficult, and the recycling process itself can also result in the release of hazardous chemicals. The environmental impact of PVC has led to heightened regulatory scrutiny globally, prompting a strong push for more sustainable practices across the industry. This regulatory pressure can translate into increased production costs for manufacturers and necessitates significant investment in research and development to create more eco-friendly alternatives. Concurrently, growing consumer awareness and government initiatives focused on environmental sustainability are driving a rising demand for eco-friendly materials and responsible production processes.

The industry’s reliance on petroleum-based products for PVC resin renders it vulnerable to price volatility in global oil markets. Such fluctuations can directly impact manufacturing costs, affecting profit margins and overall market stability. PVC coated fabrics face considerable competition from alternative materials. Notably, cotton-jute fabric has emerged as a stiff competitor. Moreover, polyurethane (PU) and silicone-coated fabrics are steadily gaining market share. PU-coated fabrics, in particular, are These challenges, manufacturers are actively exploring and investing in eco-friendly options within PVC coating processes and developing entirely new, more sustainable fabrics. It is imperative for the industry to prioritize research and development into bio-based and phthalate-free plasticizers. Furthermore, exploring and adopting fully recyclable coated fabric alternatives is crucial to mitigate environmental concerns associated with traditional PVC and to meet evolving regulatory requirements and consumer expectations.

The development of bio-based and phthalate-free plasticizers, derived from renewable resources such as vegetable oils and citric acid, offers safer alternatives to traditional phthalate-based plasticizers. These are projected to capture a larger market share due to their versatility, durability, and superior resistance to water and UV light. While PVC has historically maintained a significant market share due to its cost-effectiveness, the increasing shift towards eco-friendly alternatives may lead to a slower growth rate for traditional PVC options compared to PU and silicone. The emergence of substitute materials that offer comparable benefits without the associated environmental drawbacks poses a direct threat, as both consumers and manufacturers actively seek more sustainable choices.

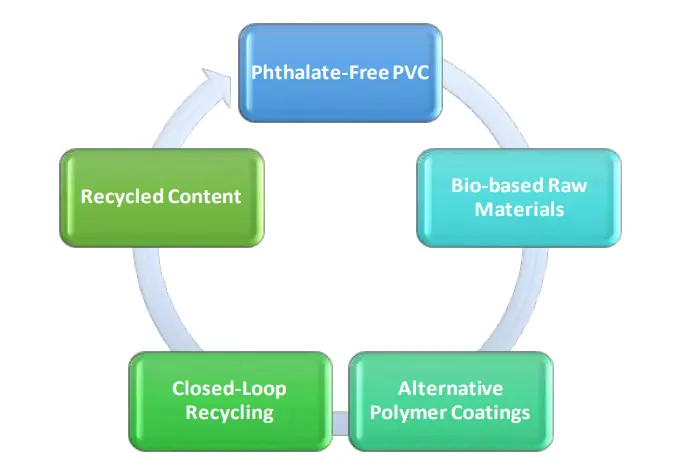

These challenges, manufacturers are actively exploring and investing in eco-friendly options within PVC coating processes and developing entirely new, more sustainable fabrics. It is imperative for the industry to prioritize research and development into bio-based and phthalate-free plasticizers. Furthermore, exploring and adopting fully recyclable coated fabric alternatives is crucial to mitigate environmental concerns associated with traditional PVC and to meet evolving regulatory requirements and consumer expectations. The development of bio-based and phthalate-free plasticizers, derived from renewable resources such as vegetable oils and citric acid, offers safer alternatives to traditional phthalate-based plasticizers.

These are projected to capture a larger market share due to their versatility, durability, and superior resistance to water and UV light. While PVC has historically maintained a significant market share due to its cost-effectiveness, the increasing shift towards eco-friendly alternatives may lead to a slower growth rate for traditional PVC options compared to PU and silicone. The emergence of substitute materials that offer comparable benefits without the associated environmental drawbacks poses a direct threat, as both consumers and manufacturers actively seek more sustainable choices. Phthalate-Free PVC Bio-based Raw Materials Alternative Polymer Coatings Closed-Loop Recycling Recycled Content increasingly being adopted in flexible PVC products, driven by stricter regulations and growing health concerns.

For instance, BASF SE has launched a new range of bio-based eco-friendly plasticizers for use in the automotive, construction, and consumer goods sectors, helping manufacturers meet stringent environmental regulations and consumer demand for greener products. The industry faces critical challenges, particularly concerning the environmental impact of traditional PVC production and disposal. This has led to increased regulatory scrutiny and a growing demand for sustainable alternatives, intensifying competition from other coated fabrics and innovative, eco-friendly materials. This dynamic necessitates a forward-looking approach from manufacturers and suppliers.

Companies like Rivertex are at the forefront of developing revolutionary ranges of non-toxic, lightweight, heat-sealable, and 100% recyclable coated fabrics (e.g., Rivercyclon®). These innovations aim to replace traditional PVC coated fabrics at comparable costs, significantly reducing reliance on non-renewable resources and environmental pollution. Companies should actively highlight and communicate their sustainable manufacturing processes and the recyclability aspects of their PVC products. This transparency will appeal directly to the growing segment of environmentally conscious consumers and enhance brand reputation.

04:15 PM, Oct 17

1.webp)

1.webp)

.png)

31.PNG)

31.PNG)

51.PNG)

41.PNG)

1.PNG)

1.PNG)